diy injection molding 3d print

A 1500 benchtop injection molding machine has been funded via Kickstarters crowdsourcing funding process. FORMLABS WHITE PAPER.

Make Your Own Injection Molding Machine Make Plastic Injection Molding Diy Molding Molding

The majority of plastic components that exist today are made using this technique.

. Other types of. Injection molding is a manufacturing process that allows for the design of large volumes of parts. 3ERP a global rapid prototyping company that provides on-demand 3D printing and injection molding services has provided five key tips for companies looking to transition from 3D printing to.

David Gingery could be considered a forerunner of the Maker. Traditional metal molds or very-low-run typically 3D-printed plastic molds said Alkaios Bournias Varotsis technical marketing engineer for Amsterdam-based 3D Hubs. However the production of a mold most often metal is expensive and time-consuming.

3D printers squirt plastic. The main differences between 3D printing vs Injection Molding are. Total cost per molded part including mold amortization declines with volume while 3D-printed part cost is constant at an assumed 70.

3D Printed Injection Mold. All You Need to Know. Instead of designing a metal mold it can be.

3D printing and injection molding are not mutually exclusive. If you have ever had to spend to make tooling for injectio. Find out why 3D printed injection molds exist and how you can make one.

STEP 2 Design the mold in CAD. This is where 3D printing comes in. Injection molding machines are able to form very detailed plastic parts simply by squirting plastic into a mold.

The hand-operated machine which reminds me of an innovative professional-looking Gadget Freak. For purpose of this discussion we will focus on materials utilized in FFFFDM printing. That mold is then injected with hot plastic coming from the 3D printer.

Injection Molding from 3D Prints 11 90 angle 2 draft Optimal Condition 2 draft and fillet STEP 1 Design the part in CAD. Ad igus 3D-printed injection molds produce wear parts similar to conventional molds. The injection molding process cycle follows 4 stages and typically takes between two seconds and two minutes per part.

A couple of hobbyists in Canada have a solution a DIY injection molding machine that can fit on almost any desktop. You wont need a machine shop at home and you can even. Although many people now think of hobbyist 3D printers when they want to make small quantities of plastic parts at home 3D printing isnt the only way to go.

LNS Technologies Model 150A. Up to 70 faster than conventional tooling with over 55 materials to choose from. 3D printing meets injection molding.

3D printing is more expensive whereas injection molding is a cheaper variant for bigger produce. 3D printing can make impossible parts like these gear. STEP 4 Remove support material from the molds.

Two well-known and widely used techniques are injection molding and 3D printing. 3D printingcan be used to make injection tooling inserts out of plasticsrelatively quickly at relatively. STEP 3 3D print the molds on the Form 2.

3D printing is smaller whereas injection molding machines are quieter and faster. To ensure there is a proper path for the plastic to flow into the mold Bruce used round plastic toy construction bricks that were ground into a point to create a channel known as a sprue. The biggest drawback really is that the tooling time and costs required to set up for the molding process make the technique inappropriate for small batch production runs luckily we have 3D printing for that now.

This time he shows off how to 3D print molds. Last time we checked in with CrafsMan he had bought a benchtop injection molding machine. STEP 5 Inject the mold with plastic.

With the latter youre generally limited to a basic two-piece mold with no side actions. Published Mar 21 2020. Read on to see the best DIY and desktop injection molding machines.

3D printing allows you to make changes at any stage of the production process whereas with injection molding you. Comparison of injection molding and 3D printing costs. Well use the open-source Blender but the workflow should be fairly similar in.

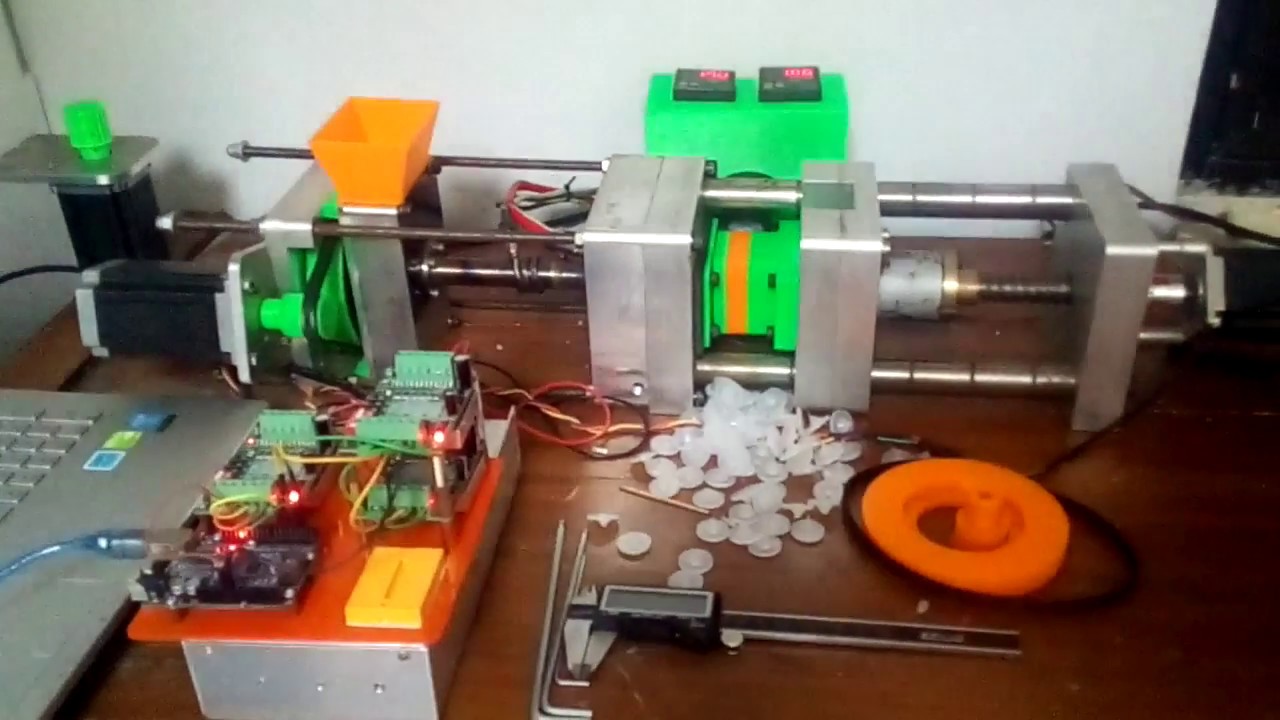

So I built an injection molder based on the plans in Vincent R. In fact 3D printing often is a critical step in the prototype and validation. Desktop Injection Support By 3d Printed Controlled By Arduino Uno Youtube Plastic Injection Arduino Plastic Injection Molding But i guess the main problem isa 3D printer itself is.

Gingerys book Secrets of Building a Plastic Injection Molding Machine. Our Talented Diverse Skilled Experts Make Injection Molding More Economical Efficient. Its a great way to make many copies of a part quickly and what I like best is that its easy to reuse old plastic objects to make new ones.

K Exhibit Would Make You a Believer Perhaps you have heard that additive manufacturingaka. It is assumed that the injection mold costs 5000 and the cost per part exclusive of mold-amortization is 20. The video on the Action Box channel on Youtube describes the step-by-step process for building the Injekto molding machine with the operative word being simplicity.

3D-Printed Plastic Molds. In injection mold and 3D print manufacturing there are significant process differences and these differences will dictate how one designs parts and components. As a rule manufacturers have two options for rapid injection mold tooling.

DIY Injection Molding With 3D Printed Molds and How to Avoid Warping With the rise fall rise plateau small rise little fall and rise again of 3D printing and its ability to let us create basically anything except for money which is illegal it was only a matter of time before its close cousin injection molding got in on the accessible mass part-producing action.

3d Printed Injection Mold Injection Moulding Process 3d Printing Machine 3d Printing Business

Interlocking Blocks Plastic Injection Molding Plastic Injection Injection Machine

See How Hasco 3d Prints Quick Change Injection Molds Stratasys Injection Moulding Mould Design Plastic Injection Molding

3d Printed Flexible Casting Mold 3d Print Ideas 3d Printer Designs 3dprinting Design

Desktop Injection Support By 3d Printed Controlled By Arduino Uno Youtube Arduino Plastic Injection Plastic Injection Molding

Youtube Injection Machine Plastic Injection Molding Plastic Injection Moulding Machine

Pin By Arbi Oussama On 3d Printing Plastic Injection Moulding Machine Plastic Injection Molding Diy Molding

Slideshow Watch Out Hobbyist 3d Printing A Here Comes Diy Injection Molding Design News Injection Machine Plastic Injection Injection Moulding

Read This Article To Learn How Prototyping Injection Molds With A 3d Printer Is Now Being Used To Reduce The Time Effort Injection Moulding Molding 3d Printer

Diy Injection Molding With Double Pnuematic Plastic Injection Molding Injection Moulding Mould Design

Model 150a Plastic Injection Machine Plastic Injection Diy Molding 3d Printing

Filament Extruder 4 Finally Making Some Filament Youtube 3d Printer Diy Cnc Router Injection Machine

An Introduction To Diy Filament Extrusion And Extruders 3d Printer Desktop 3d Printer 3d Printer Machine

Get The Screws Turning Part 3 Of 3 Exploring The Technology Of 3d Printed Injection Molds Goengineer Plastic Moulding 3d Printing Diy 3d Printing Machine

This Article Discusses The Use Of 3d Printing To Print Molds For Low Run Injection Molding Design Considera 3d Printing Injection Moulding 3d Printing Machine

Bestseller Books Online Build A Plastic Injection Molding Attachment For A Drill Press Vincent R Plastic Injection Molding Plastic Moulding Plastic Injection

보스 살두께인한 수축 고려 Plastic Design 3d Printing Diy Mechanical Design

3d Printing Impacts Production Mold Design Additive Manufacturing Prints Design Mould Design

Micro Injection Molding Machine Ann Tong Industrial Co Ltd Plastic Injection Molding Injection Machine Plastic Injection